Essential Healthcare Supply Chain Innovations for Enhanced Efficiency

-

Kara L. Nadeau, Healthcare Industry Contributor

Kara L. Nadeau, Healthcare Industry Contributor

The COVID-19 pandemic highlighted vulnerabilities in healthcare supply chains, prompting a shift towards innovative solutions for enhanced resilience and efficiency. This post delves into Healthcare Supply Chain 2.0, showcasing how AI, automation, and advanced technologies like 3D printing are revolutionizing procurement, inventory management, and sustainability, ultimately reducing costs and improving patient care.

Table of Contents

Introduction: Why Healthcare Supply Chain 2.0 Matters

The fragility of the healthcare supply chain was exposed during the COVID-19 pandemic and even with steps taken by leaders over the past five years to build a more resilient supply chain, health systems are still feeling the pain of continued disruptions and supply shortages.

Among healthcare leaders surveyed, 80% expect challenges to worsen or remain the same in 2025 and on average, supply shortages are increasing the cost of providing care by $3.5 million per year for a medium-size health system.

Healthcare providers and their suppliers have made tremendous progress in optimizing supply chain operations through digital transformation—automating routine tasks, driving operational efficiency, taking steps to maintain optimal inventory levels and reducing operational costs—through the transition to cloud-based systems and the application of digital tools and advanced analytics.

But given the ongoing threats, the healthcare system can't stop now—stakeholders must continue innovating to meet current and future challenges.

Let's explore three key areas for navigating the supply chain fragility crisis through resiliency breakthroughs: Artificial intelligence (AI), expanded process automation, and advanced technologies.

Innovations Driving Healthcare Supply Chain 2.0

When thinking about healthcare supply chain advancements, most envision innovations inside the box that defines supply chain: Technologies for improved contract management, procurement, optimized distribution centers, hospital inventory management, etc. There is no doubt improvements in these areas are critical to strengthening the supply chain, given the countless success stories from healthcare organizations.

But as health systems embrace the digital transformation revolution, other modern healthcare advancements outside of traditional supply chain operations are showing promise and becoming applicable to the field.

AI-Powered Medical Coding and Beyond

Many medical/surgical supplies used in patient care delivery are billable to the patient and payer—public or private. If supply chain leaders assign Healthcare Common Procedure Coding System (HCPCS), revenue and billing codes to supplies in their resource planning (ERP) system item masters, they can support accurate and complete billing and reimbursement for their health systems.

Some health systems have turned to AI-powered medical coding to translate documentation from patient procedures, including supplies used, into standardized codes required by payers. According to the AAPC (previously known by its full name American Academy of Professional Coders):

"AI can improve efficiency, accuracy, and productivity in medical coding and billing practices by leveraging natural language processing, machine learning, and automation."

Why is this important to supply chain teams? Here are two reasons:

-

Greater revenue generation: Medical supplies represent a significant portion of health systems' budgets. U.S. hospitals reported over $57 billion in combined medical and surgical supply costs, averaging $15.4 million per hospital, according to the latest data from Definitive Healthcare. Accurately billing for supplies used in patient procedures generates revenue for health systems.

-

Opening the door to broader AI innovation: Stakeholders in health systems, including supply chain, have been looking for evidence of artificial intelligence use cases that deliver return on investment. Supply chain shares similarities with their finance and billing department peers when it comes to the need for automating routine tasks and reducing human error, not to mention the ability to address labor shortages and impact job satisfaction through reduction of manual processes. A win for AI powered systems in medical coding could signal a win for AI plays in supply chain.

“It’s not foolproof, but it can certainly increase productivity,” said Dawson Ballard, a coding auditor and educator for Chicago-based Rush University Medical Center, speaking to AI systems for medical coding.

Use Cases for AI in Supply Chain Optimization

Looking specifically at AI technologies designed for the healthcare supply chain, there are many proven and potential use cases leveraging different forms of AI, including machine learning (ML). Here are several examples:

Medical/surgical supply order automation: Within their digital procure-to-pay (P2P) ecosystems, trading partners are leveraging advanced AI algorithms and logic incorporating ML and custom rules to help decrease exceptions.

AI enabled automation in P2P processes drives greater efficiency and accuracy, helps get the right supplies at the right prices in the right quantities to the right locations, and generates cost savings by improving staff resource allocation.

GHX has long been a leader in healthcare P2P process automation with its Enterprise Exchange, featuring robust workflow management tools, compliance insights, business intelligence and contract validation. The technology solutions provider is committed to expanding the value of AI in P2P processes and beyond (more on that later in this post).

In this brief video interview, Julie Trudeau, System Manager Procurement for Aspirus, speaks to her health system's success with P2P automation: “Nobody touches those orders anymore. These are 20, 30, 40-line orders that if I don't have to have someone manually typing those, that's amazing.”

Bill only order automation: Automation of bill-only implant and consignment orders long eluded supply chain leaders due to the complexity of inventory management, vendor coordination and the need for precise data integration.

Ordering and inventory management of these high-dollar, high-risk items (requiring detailed documentation in the patient record) has historically been handled manually by clinical teams outside of enterprise resource planning (ERP) systems. This has added complexity to supply chain processes, increased human error, and taken clinician time away from patient care.

Healthcare providers and suppliers have come together with their supply chain technology solutions provider GHX to develop an ML driven solution to automate complex order scenarios, including bill-only implant and consignment orders, within their ERP systems.

In this blog post, GHX's Susan LaFountain dives deep into industry challenges around bill-only orders and how this solution impacts both providers and suppliers.

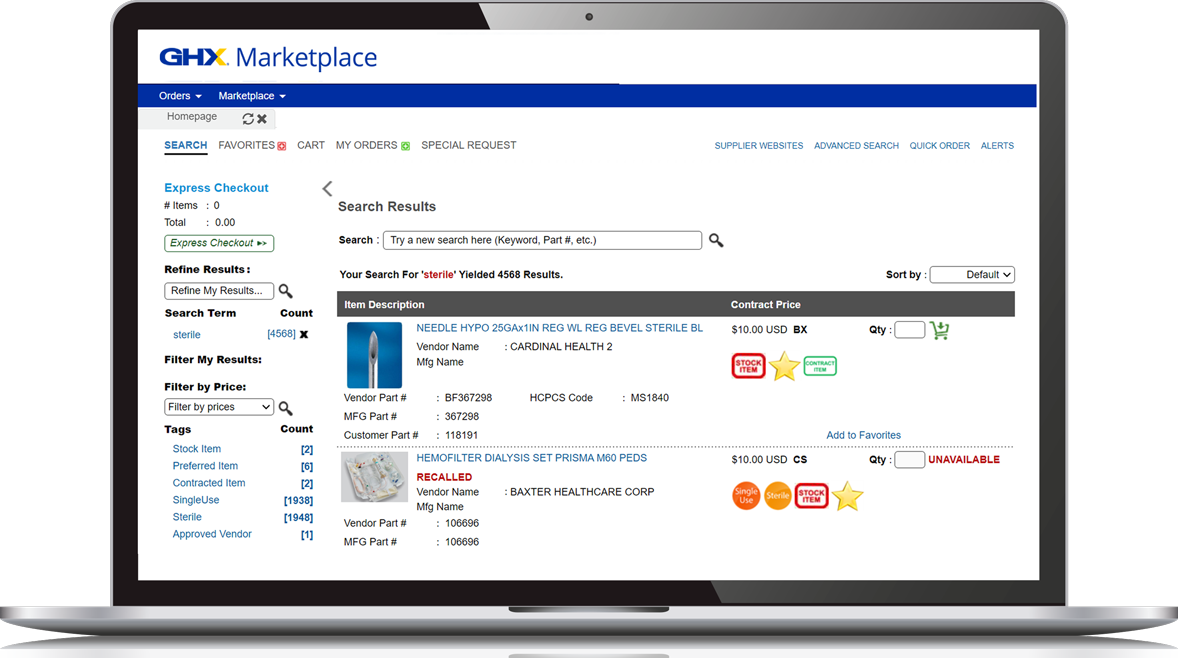

Directed buying: Healthcare supply chain teams work hard to negotiate favorable contracts and pricing for medical supplies, but driving formulary and contract compliance among requisitioners can be a significant challenge that negates cost savings opportunities. Off formulary purchases of critical supplies can also jeopardize patient care and safety.

GHX Marketplace, a virtual ecommerce solution, uses ML to direct requisitioners to their healthcare organization's preferred sources of supply. It drives purchase activity to contracted items and preferred vendors, maximizing price incentives, increasing efficiency and delivering the perfect order. It can also be used to support key health organization initiatives, such as sustainable procurement, by highlighting suppliers dedicated to reducing carbon emissions and other green initiatives.

Carmen Winfield, Vice President, Supply Chain, McLeod Health speaks to her health system's use of GHX Marketplace in a brief video interview, stating: “It has an Amazon feel, it’s very easy to you, but you can use that to drive spend compliance.”

Value analysis and clinical integration: COVID-19 brought together supply chain and healthcare providers in making supply decisions around substitutes for backordered items, such as personal protective equipment.

Now, health systems are striving to bring more clinical integration into their supply chains, aligning value analysis teams, frontline clinicians and supply chain leaders to make decisions around physician preference items (PPI), such as medical devices. Evidence-based data and AI analytics solutions support these collaborative efforts.

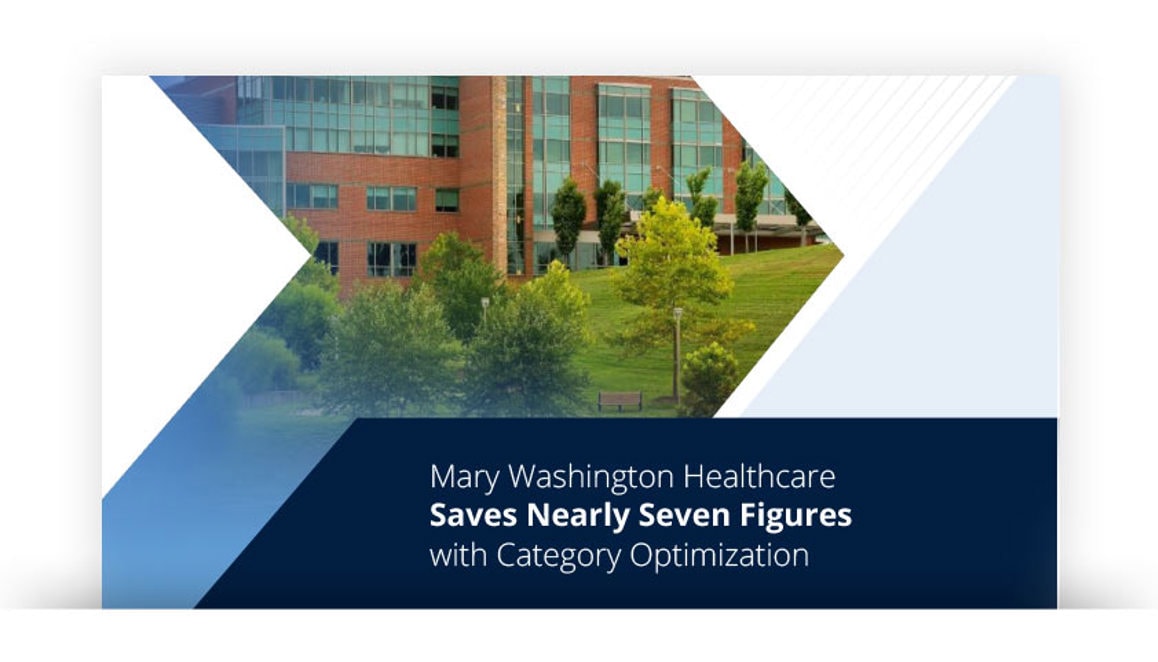

GHX Value Analysis pulls data directly from the health system's operational and purchase history and applies advanced ML-based analytics and capabilities, rapidly surfacing evidence-based insights on physician device utilization and potential savings strategies. Supply chain leaders, value analysis teams and frontline clinicians use this intelligence to make informed decisions in vendor and device section.

In this brief video, Richard Kirchgessner, value analysis manager, Mary Washington Healthcare (MWHC), speaks to his health system's success with GHX Value Analysis, stating, “One vendor went from being our most expensive stent to being the most competitive, which is pretty astonishing.”

Emerging AI Innovations

Looking ahead, members of the GHX leadership team shared key focus areas for leveraging AI in supply chain in 2025 and beyond:

-

Predicting and mitigating supply disruptions: AI will analyze complex supply chain patterns, flag potential risks and suggest alternatives to maintain continuity. This will enhance resiliency and help ensure critical medical supplies reach the right place at the right time, supporting value-based care by helping to reduce waste and improve patient outcomes. (More on this use case later in this post under Generative AI in Supply Chain Management)

-

Optimizing pricing and transactions: In procure-to-pay and contract-to-cash workflows, AI will streamline price management by identifying discrepancies, automating resolutions and providing transparent, efficient transactions that benefit all stakeholders.

-

AI-powered exception management co-pilots: Intelligent co-pilots will assist supply chain teams by identifying and resolving operational anomalies, such as delayed shipments, mismatched purchase orders or demand spikes. These tools will automate repetitive tasks, provide real-time recommendations, and enable teams to focus on higher-value activities.

3D Printing as a Game Changer

In response to major disruptions in the supply chain, manufacturers and health systems have employed AI technologies in 3D printing of personal protective equipment, ventilator parts, and other critical medical devices and medical equipment.

As seen during the COVID-19 pandemic, 3D printing can be used to addresses shortages in inventory levels. According to researchers, "This experience has led to increased awareness and adoption of 3D printing in the healthcare industry, with an increasing number of applications being considered."

Leveraging AI tools, 3D printing can be used to manufacture highly customized surgical instruments and prosthetics personalized to patients. Beyond the on-time availability and patient care benefits that 3D printing provides to enhance resilience, with timely delivery of needed items printed on-demand, this technology can also impact cost effectiveness.

Producing items on a 3D printer can reduce production costs compared to traditional manufacturing, and can reduce transportation costs when items are printed local to where they are needed.

Today, health systems are exploring the possibility of using 3D printing to produce human organs on demand. Stanford bioengineer Mark Skylar-Scott stated:

"In three and a half years, my lab plans to have a 3D-printed human organ inside a pig model. We hope that large animal study becomes a springboard to then lay out the milestones needed for a first in-human trial. That will likely be more than a decade away. There’s a lot of work to be done, but there are real forward steps that we're taking."

Generative AI in Supply Chain Management

Healthcare providers are using predictive analytics in procurement and planning, employing AI to analyze vast amounts of historical data to predict future demand for medical/surgical supplies. This has improved demand forecasting and the ability to stock optimal inventory levels.

When hospital supply chain teams share analytics that predict demand with their suppliers, it can improve supplier performance in delivering the needed items—matching supply with demand. Demand forecasting can also improve supplier relationships because it helps medical/surgical manufacturers optimize their own supply chain planning—from sourcing raw materials to producing finished goods.

Faced with uncertainty for the future, including when the next supply chain disruptions will hit and in what form (e.g., natural disasters, infectious diseases, supplier performance issues, geopolitical factors), healthcare organizations and manufacturers of critical supplies must also pursue healthcare supply chain innovations that enable them to predict potential threats and act rapidly and with precision to mitigate impacts to patient outcomes. That is where Gen AI offers substantial benefits in crisis management.

Compared with predictive analytics, which inform stakeholders of what could occur, prescriptive analytics tools analyze data to propose actions based on those predictions. According to Gartner, integration of GenAI can augment both predictive and prescriptive analytics "expanding their impact and reach, securing competitive advantage, and driving superior value outcomes."

Consider a healthcare supply chain team faced with shortages of a critical supply because of an unexpected event that halted manufacturer production. Using GenAI enabled prescriptive analytics, the team could model the scenario and surface solutions—perhaps switching to a manufacturer with production plants that were not impacted by the event.

Strategies for a Resilient and Automated Supply Chain

Healthcare supply chain leaders have navigated the overwhelming challenges of the pandemic and continue to face supply disruptions that threaten patient care continuity.

Leveraging digital transformation to automate processes and access the accurate, complete and real-time data needed to train AI technologies, they are safeguarding against fragilities that surfaced during the pandemic and advancing their ability to proactively address future uncertainty.

Lessons from Past Vulnerabilities

The drive for digital transformation in healthcare supply chains has served to rapidly advance cloud system and AI-enabled solution adoption. A recent survey of healthcare executives found more than half believe AI will have a significant impact on the healthcare industry.

While there are the obvious benefits that come with employing AI to drive decision making around inventory management and optimization, the enhancements enabled by AI and process automation go even deeper - driving out inefficiencies and costs by reducing repetitive tasks and the risk for human error.

Data-Driven Decision-Making

The role of healthcare supply chain has transformed from tactical to strategic through the availability and use of actionable insights derived from key data sources, including the item master, P2P transactions, electronic health record (EHR) systems and other integrated solutions.

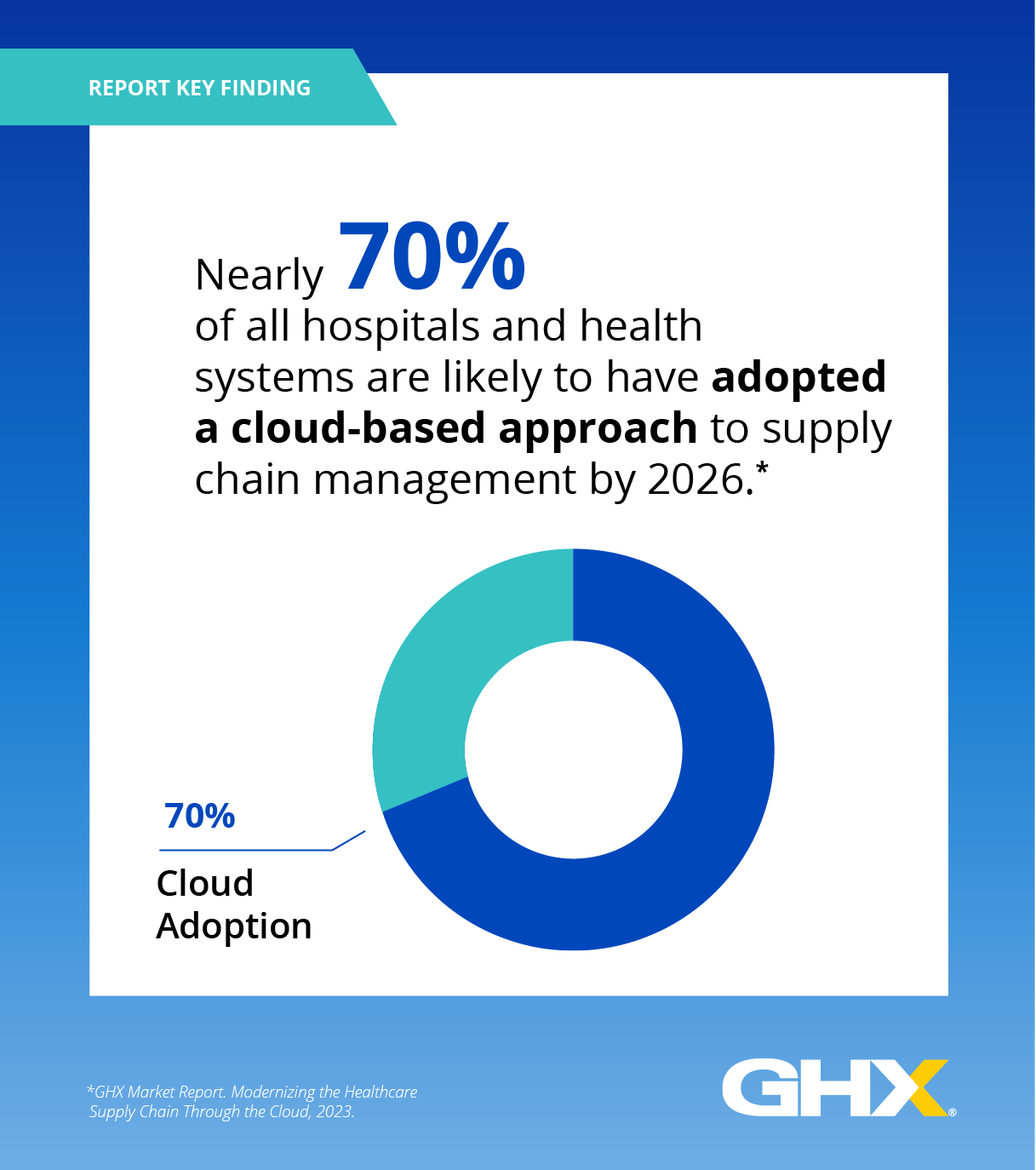

The shift to cloud ERP and EHR systems and cloud-based supply chain management (SCM) solutions has facilitated greater integration and data sharing, providing supply chain leaders enhanced visibility and control.

Nearly 70% of all hospitals and health systems are likely to have adopted a cloud-based approach to supply chain management by 2026, according to a GHX survey. Among those surveyed, 78% said the move to cloud enhanced supply chain decision making.

Automation in Accounts Payable

Referred to as the "final mile" of P2P processes, accounts payable (AP) operations are critical to healthcare system success, specifically cash management, forecasting and cost savings. Automation of supplier invoice processing and payments, and the ability to make payments on time, can also safeguard supply availability, reducing the risk for credit holds and supply shipment disruptions.

AP is increasingly shifting from paper-based manual to digital, automated processes to reduce costs and improve efficiency (click here for a tool to calculate how much your organization could potentially save). Real-time invoice and payment tracking and AI-enabled automated exception handling through PO-to-invoice matching helps reduce errors and speed approval time.

Speaking to his organization's invoice automation success with the GHX eInvoicing solution, Chuck Payne, director of Disbursement for Children's of Alabama said, "It’s been tremendously helpful in planning upcoming and future payments, which has a direct impact on our bottom line.” You can access the full case study here.

The Future of Healthcare Supply Chains

Supply chain operations are constantly evolving as healthcare organizations expand automation and AI technologies more broadly to tackle deeper layers of cost and risk. At the same time, leaders are more closely aligning procurement strategies with their healthcare organizations' broader objectives.

Toward Sustainability and Localization

Initiatives such as The Joint Commission's (TJC) Sustainable Healthcare Certification program are compelling green initiatives in healthcare supply chain, and AI algorithms are supporting these efforts. As mentioned previously in this post, hospitals are using ML enabled directed buying to direct requisitioners to vendors and products designated as environmentally responsible.

This includes not only items manufactured using green materials and sustainable production practices, but also suppliers that support local sourcing. Decentralized supply chains with localized manufacturing hubs shorten the distance between product production and point of use, decreasing transportation needs and reducing carbon emissions.

Expanding the Role of Emerging Technologies

As Deloitte detailed in a recent report, blockchain technology is being used in various industries to strengthen global supply chains—supporting the ability to predict risk; enhancing visibility and traceability for critical product components; increasing data accuracy, immutability, and trust among value partners. These same benefits can be derived by healthcare organizations and their trading partners, according to the report authors.

They note how blockchain "can serve as an add-on enterprise solution that increases value while still maintaining existing enterprise resource planning (ERP) software systems or other current systems."

They add that "blockchain technology is mature enough to interface with, and take advantage of, other emerging technologies such as Internet of Things (IoT), smart contracts (pieces of code stored on a blockchain), and artificial intelligence (AI) to provide an enhanced and secured supply chain."

Conclusion: Embracing Supply Chain 2.0

The digital transformation of the healthcare supply chain, with cloud-based systems and solutions, seamless integration, process automation, and AI powered digital insights, is central to strengthening resiliency and overcoming the fragility crisis.

Leaders working to make the case for modernization in their healthcare organizations have access to a vast number of resources demonstrating the benefits and ROI. As the company that pioneered healthcare’s leading cloud-based supply chain network, GHX has many assets on its website, including healthcare provider case studies demonstrating operational, financial and clinical performance improvements.

For leaders wanting to connect in-person with their peers, the GHX Summit is an annual, in-person event that brings together healthcare providers, suppliers and distributors for three days of real-world learning, best practice sharing and networking. A key focus is sharing ideas and best practices around collaboratively building an agile, cost-effective, and predictive healthcare supply chain. Details on Summit25 can be accessed here.

FAQs

-

What is Healthcare Supply Chain 2.0?

It refers to the next generation of supply chain management powered by AI, automation, and advanced technologies to improve resilience and efficiency. -

How does 3D printing impact healthcare supply chains?

3D printing helps address shortages, enables localized manufacturing, and reduces dependency on traditional suppliers. -

What are the benefits of automation in accounts payable?

Automation reduces manual errors, speeds up invoice processing, and lowers administrative costs. -

How does AI enhance supply chain resiliency?

AI predicts disruptions, optimizes inventory levels, and supports data-driven decision-making. -

What technologies will shape the future of healthcare supply chains?

Emerging technologies like blockchain, IoT, and generative AI will play crucial roles in improving transparency, efficiency, and sustainability.

Kara L. Nadeau

Healthcare Industry Contributor

Kara L. Nadeau has 25+ years’ experience as a writer/content creator for the healthcare industry, serving clients in fields including medical supplies and devices, pharmaceuticals, supply chain, technology solutions, and quality management.